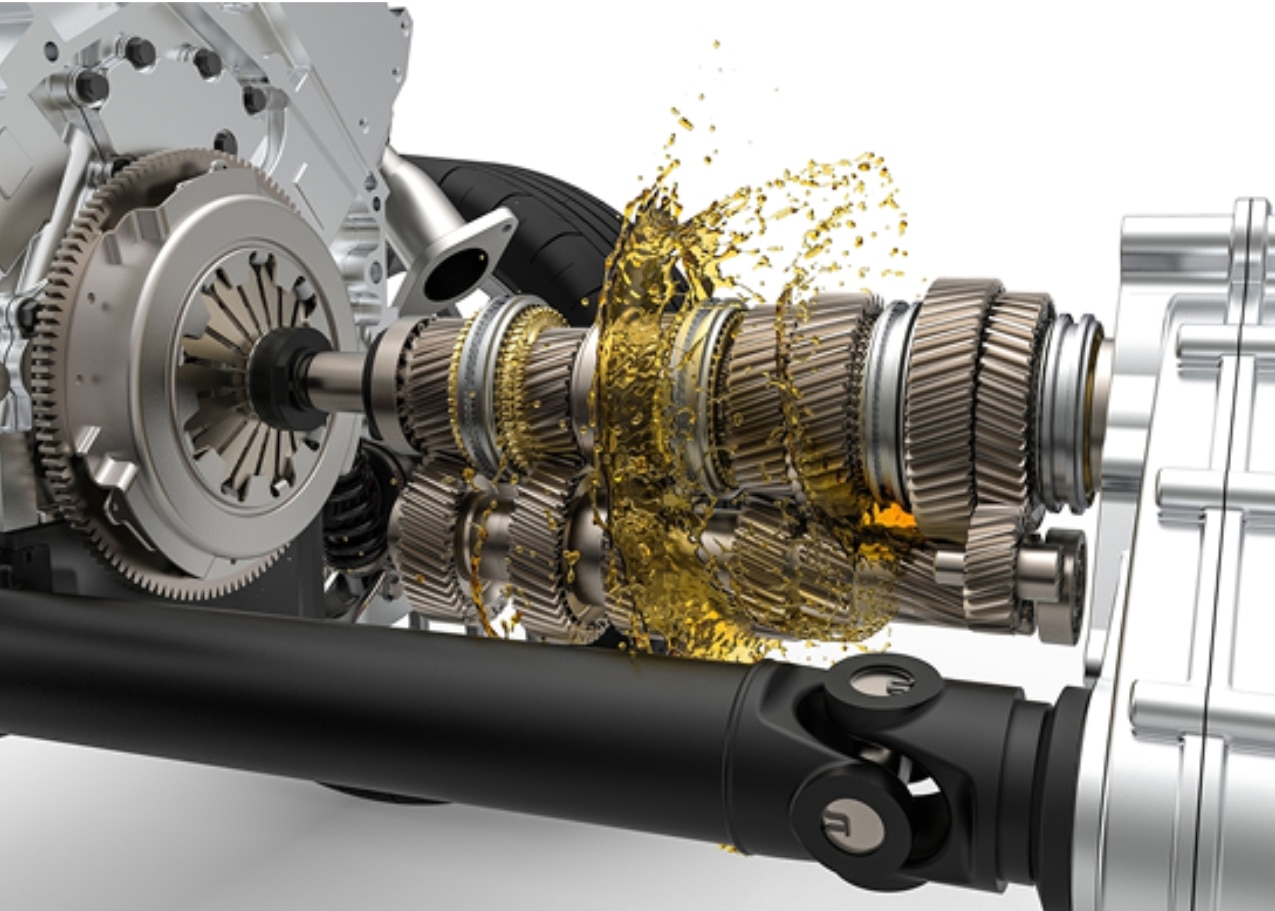

Shaft Mounted Speed Reducer Manufactured & Supplied by JRB Engineering Works JRB Engineering Works is a trusted manufacturer and supplier of high-performance Shaft Mounted Speed Reducers (SMSR), designed to provide efficient speed reduction and high torque transmission for a wide range of industrial applications. Our shaft mounted speed reducers are engineered for rugged performance, compact installation, and reliable operation in demanding working conditions. The optigear Shaft Mounted Speed Reducer provides a very convenient method of reducing speed, since it is mounted directly on the driven shaft instead of requiring foundations of its own. It eliminates the use of one and sometimes two flexible couplings and external belt take-up arrangements. A torque-arm anchors the Reducer and provides quick easy adjustment of the V-Belts by means of its turnbuckle. The Optigear Speed Reducer is manufactured in eight gear case sizes, designated by the letters B to J. The eight sizes may have anyone of three nominal gear ratios 5: 1, 13:1 and 20: 1. These reducers are especially suitable for conveyor systems and material handling equipment where direct mounting on the driven shaft is required, eliminating the need for complex foundations and couplings. Robust Design & Efficient Performance The Shaft Mounted Speed Reducer from JRB Engineering Works features a compact and heavy-duty construction that allows direct mounting on the driven shaft. The reducer is supported by a torque arm that absorbs reaction forces, ensuring stable and vibration-free operation. Manufactured using high-quality cast iron housings and precision-cut gears, our speed reducers offer excellent strength, reduced noise, and high mechanical efficiency. Proper sealing and oil bath lubrication ensure smooth operation and long service life with minimal maintenance. Key Features of Shaft Mounted Speed Reducer Compact and space-saving design Direct shaft mounting eliminates couplings High torque transmission capability Heavy-duty cast iron housing Precision-hardened helical gears Smooth, low-noise operation Oil bath lubrication for long life Easy installation and low maintenance Technical Specifications Product Type: Shaft Mounted Speed Reducer (SMSR) Housing Material: Cast Iron Gear Type: Helical Gears Mounting: Shaft Mounted with Torque Arm Input Arrangement: Solid shaft / Hollow shaft Output: Direct shaft mounting Speed Ratio: Multiple ratios available Lubrication: Oil bath lubrication Application Duty: Continuous & Heavy Duty Applications Shaft Mounted Speed Reducers supplied by JRB Engineering Works are widely used in: Belt conveyors Bucket elevators Material handling systems Cement plants Sugar mills Mining and quarry equipment Power plants Fertilizer and chemical industries Advantages of JRB Engineering Works SMSR Reduced installation time and cost Compact layout with minimal space requirement High reliability under heavy load conditions Reduced power losses and improved efficiency Long operational life with minimal downtime Why Choose JRB Engineering Works? At JRB Engineering Works, we focus on quality, durability, and customer satisfaction. Our Shaft Mounted Speed Reducers are manufactured using advanced technology and strict quality control procedures to meet industry standards and customer requirements. We offer customized solutions, competitive pricing, timely delivery, and strong after-sales support, making us a preferred partner for power transmission solutions. Customization & Technical Support We provide complete customization of Shaft Mounted Speed Reducers based on: Power and torque requirements Speed reduction ratio Shaft size and mounting orientation Application-specific operating conditions Our experienced technical team assists customers in selecting the most suitable speed reducer for maximum efficiency and performance. JRB Engineering Works – Delivering reliable, efficient, and durable Shaft Mounted Speed Reducers for modern industrial applications.

About OPTIGEAR

The Best Transmission Gears Manufacturer in new delhi

Products

Featured ProductsWhat We Do

Have any custom requirements?

Latest Updates

Read Our Latest Updates & News

×

![]()